会社概要

ムベアは自動車産業界のグローバルパートナーであり、高強度スプリングおよび関連製品の軽量化を実現するスペシャリストです。オーナーがファミリービジネスで築きあげたムベアの名前は、歴史と未来、そして発展の代名詞となっています。

The Mubea Way

1つ1つを見ると、これらの項目は企業理念とは言えません。しかし全てを一緒に見ると、”The Mubea Way”の全体像が把握できます。これは100年の社史の結果であり、会社の基盤を形成するものでもあります。

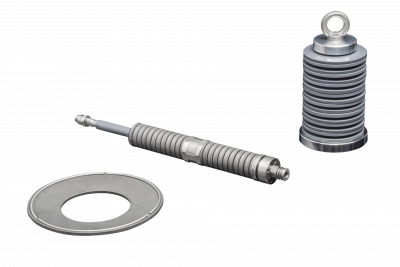

Mubea Products

With our unique products and technologies, we have become established as a world market leader. We develop individual solutions with the aim of maximizing weight reductions and offering the greatest benefits to the customer.

MUBEA Career

Our employees are our most important resource. The know-how that they possess is our greatest asset. Their team spirit and dedication are valuable parts of our identity. Join now!