公司介绍

我们是汽车行业的全球合作伙伴,也是高强度弹簧部件及相关产品的创新轻量化专家。我们是一个家族企业,我们的名字代表着长期、可持续的商业成功。

The Mubea Way

Jeder einzelne der folgenden Aspekte macht keine Unternehmensphilosophie aus – in der Summe ergibt sich jedoch ein Bild dessen, was wir „The Mubea Way“ nennen. Er ist das Ergebnis aus 100 Jahren Unternehmensgeschichte und gleichzeitig das Fundament für unser Unternehmen.

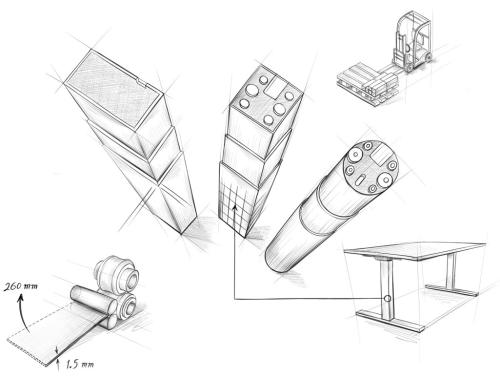

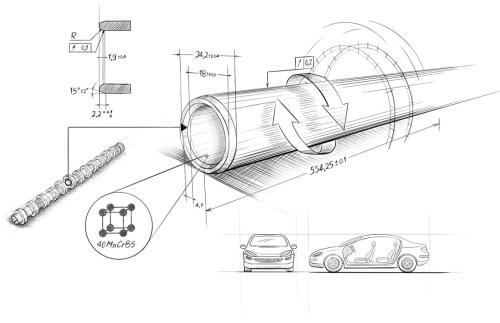

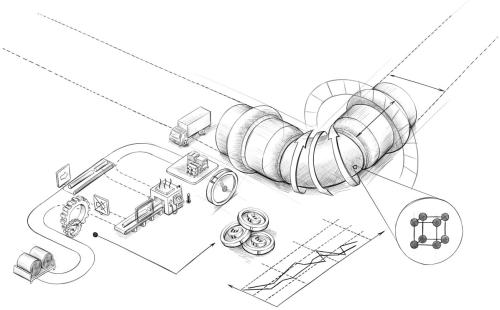

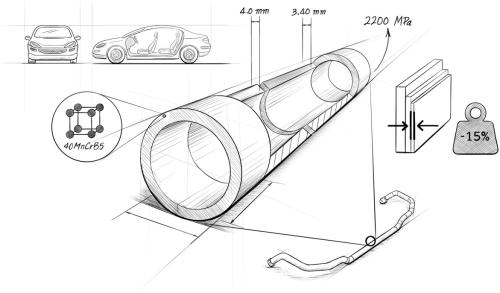

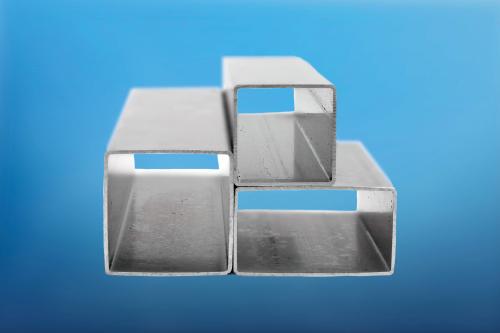

产品介绍

凭借我们独特的产品特性和创新技术,我们已成为全球市场领导者。通过开发个性化技术方案,旨在帮助客户实现最大化车身减重,同时为客户提供最大的经济利益。

MUBEA-KARRIERE

Unsere Mitarbeiter sind unsere wichtigste Ressource. Das Know-how, das sie mitbringen, ist unser höchstes Gut. Werden auch Sie Teil der Mubea-Familie.