Unternehmen

Wir sind weltweiter Partner der Automobilindustrie und innovativer Leichtbauspezialist für hochbeanspruchbare Federkomponenten und verwandte Produkte. Als inhabergeführtes Familienunternehmen steht unser Name für langfristigen, nachhaltigen Geschäftserfolg.

The Mubea Way

Jeder einzelne der folgenden Aspekte macht keine Unternehmensphilosophie aus – in der Summe ergibt sich jedoch ein Bild dessen, was wir „The Mubea Way“ nennen. Er ist das Ergebnis aus 100 Jahren Unternehmensgeschichte und gleichzeitig das Fundament für unser Unternehmen.

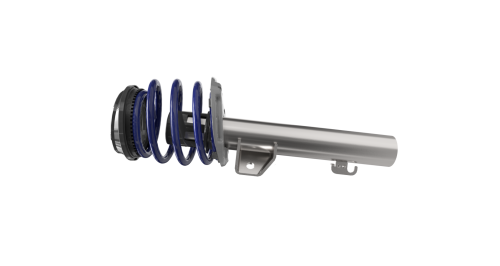

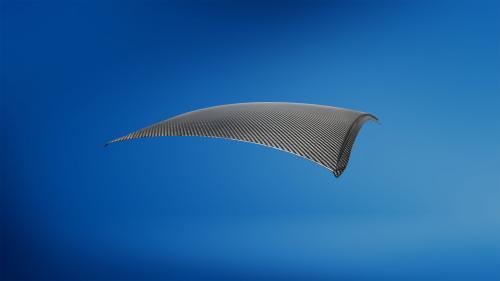

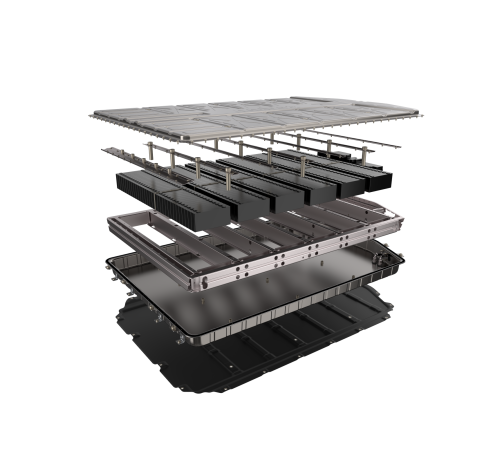

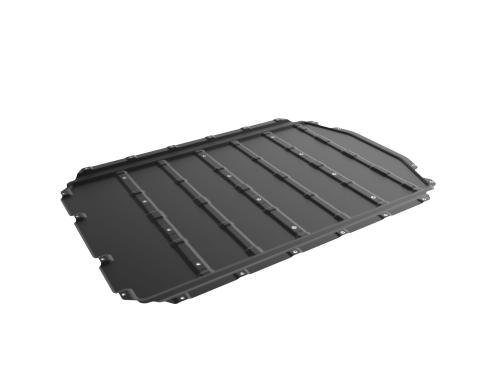

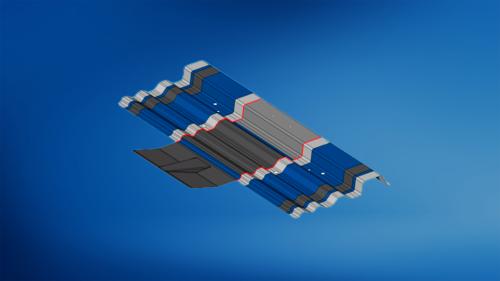

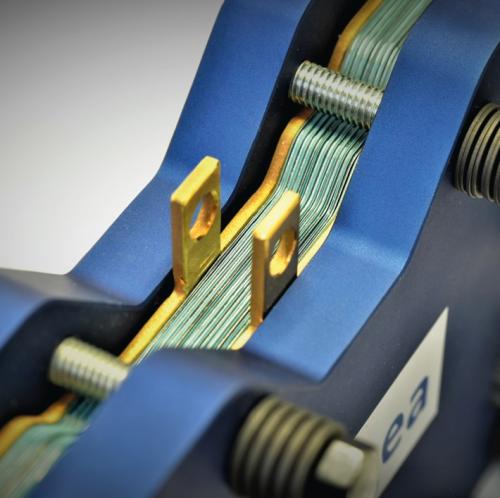

Mubea-Produkte

Mit einzigartigen Produkten und Technologien sind wir bei unseren Kunden als Weltmarktführer etabliert. Wir entwickeln individuelle Lösungen und erzielen dabei höchste Gewichtseinsparungen mit maximalem Kundennutzen.

MUBEA-KARRIERE

Unsere Mitarbeitenden sind unsere wichtigste Ressource. Das Know-how, das sie mitbringen, ist unser höchstes Gut. Werden auch Sie Teil der Mubea-Familie.